REPARACION DE SENSOR DE CIGUEÑAL EN TOYOTA

-

Upload

pepeladazo -

Category

Documents

-

view

240 -

download

1

description

Transcript of REPARACION DE SENSOR DE CIGUEÑAL EN TOYOTA

-

A12484

ECM

NE+

G2

E4

E4

16

15

NEE424

C3Crankshaft Position Sensor

Signal Rotor on Intake Camshaft

C1Camshaft Position Sensor

Crank AngleSensor Plate

W

2

W

B

1

B

2

1

B

DIAGNOSTICS ENGINEDI71

235Author: Date:

2000 MR2 (RM760U)

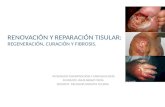

DTC P0335 Crankshaft Position Sensor A CircuitMalfunction

CIRCUIT DESCRIPTIONCrankshaft position sensor (NE signal) consists of a magnet, iron core and pick up coil.The NE signal plate (crank angle sensor plate) has 34 teeth and is mounted on the crankshaft. The NE signalsensor generates 34 signals at every engine revolution. The ECM detects the standard crankshaft anglebased on the G signal, the actual crankshaft angle and the engine speed by the NE signal.

DTC No. DTC Detection Condition Trouble Area

P0335

No crankshaft position sensor signal to ECM during cranking(2 trip detection logic)

Open or short in crankshaft position sensor circuitCrankshaft position sensor

P0335No crankshaft position sensor signal to ECM with enginespeed 600 rpm or more (2 trip detection logic)

Crankshaft osition sensorCrank angle sensor plateECM

WIRING DIAGRAM

INSPECTION PROCEDUREHINT: Perform troubleshooting of DTC P0335 1st. If no trouble is found, troubleshoot the following mechani-

cal system. Read freeze frame data using TOYOTA handheld tester or OBD II scan tool. Because freeze frame

records the engine conditions when the malfunction is detected. When troubleshooting, it is useful fordetermining whether the vehicle was running or stopped, the engine was warmed up or not, the airfuelratio was lean or rich, etc. at the time of the malfunction.

DI38B03

-

A03961

G and NE Signal Waveforms

G

NE

5 V/Division

20 msec./Division (Idling)

DI72DIAGNOSTICS ENGINE

236Author: Date:

2000 MR2 (RM760U)

1 Check resistance of crankshaft position sensor (See page IG1).

Reference: INSPECTION USING OSCILLOSCOPEDuring cranking or idling, check the waveform between termi-nals G2 and NE and NE+ and NE of the ECM connector.HINT:The correct waveforms are as shown.

NG Replace crankshaft position sensor.

OK

2 Check for open and short in harness and connector between ECM and crankshaft position sensor (See page IN28).

NG Repair or replace harness or connector.

OK

3 Inspect sensor installation and teeth of crank angle sensor plate (See page EM11).

NG Tighten sensor. Replace crank angle sensorplate.

OK

Check and replace ECM (See page IN28).