SFRC

description

Transcript of SFRC

-

BEFIB2012 Fibre reinforced concrete

Joaquim Barros et al. (Eds)

UM, Guimares, 2012

NUMERICAL TOOL FOR MODELING STEEL FIBER REINFORCED CONCRETE

Climent Molins*, Alba Pros

1 and Pedro Dez

1

*Departament dEnginyeria de la Construcci, Universitat Politcnica de Catalunya

Jordi Girona, 1-3 , 08034 Barcelona, Spain. e-mail: [email protected]

1 Laboratori de Clcul Numric, Universitat Politcnica de Catalunya

Jordi Girona, 1-3 , 08034 Barcelona, Spain. e-mail: [email protected] and [email protected]

Keywords: Plain concrete, Steel Fiber Reinforced Concrete, Numerical Model, Immersed Boundary methods, Pullout test, Model Validation, Direct Tension Test, Three Point Bending Test. Summary: Steel Fiber Reinforced Concrete (SFRC) allows overcoming brittleness and weakness in tension, the main drawbacks of plain concrete. The goal of the present presentation is to present an ad-hoc numerical strategy to account for the contribution of the fibers in the simulation of the mechanical response of SFRC. In the model presented, the individual fibers immersed in the concrete bulk are accounted for in their actual location and orientation. The selected approach is based on the ideas introduced in the Immersed Boundary (IB) methods. These methods were developed to account for 1D (or 2D) solids immersed in 2D (or 3D) fluids. Here, the concrete bulk is playing the role of the fluid and the cloud of steel fibers is acting as the immerse boundary (that is a 1D structure in a 2D or 3D continuous). Thus, the philosophy of the IB methodology is used to couple the behavior of the two systems, the concrete bulk and the fiber cloud, precluding the need of matching finite element meshes. In the proposed approach, the meshes of the concrete bulk and fiber cloud are independent and the models are coupled imposing displacement compatibility and equilibrium of the two systems. The concrete bulk is modeled using any nonlinear model. The constitutive model for the fibers is designed to account for the complex interaction between fibers and concrete. The fiber models are based on previous investigations describing the concrete-fiber interaction and its dependence on the factors identified to be relevant: shape of the fiber (straight or hooked) and angle between the fiber and the crack plane. 3D examples with fibers distributed and oriented randomly are reproduced using the proposed approach.

1 INTRODUCTION

The methods for characterizing Steel Fiber Reinforced Concrete (SFRC) and the quality control of the material properties clearly deserve further development. There is a current need of improving theses methodologies in order to satisfy the individual request of further using of SFRC with increasing structural responsibilities.

A number of direct and indirect tension tests are used to determine the tensile behavior of SFRC. Bending tests of prismatic beam specimens are the most used to characterize the post-cracking response of the material. Other methods have also been used for characterizing the material, such as direct tension test, the splitting test,... For example, Barcelona Test is the extension of the Double Punch Test, an indirect tension test, with SFRC and is used to study the post-cracking response of the SFRC. Moreover, pullout tests are useful because they describe all the phenomena of the SFRC not only for straight fibers (fiber debonding, matrix spalling, frictional sliding and fiber removal), but also for hooked fibers (which are the same for the straight ones but with plastic deformation magnifying the

-

BEFIB2012: Climent Molins and Alba Pros and Pedro Dez.

2

matrix spalling effects). Therefore, a numerical tool for modeling SFRC is proposed in this work allowing simulating all the

tests. The goal of the present work is to present an ad-hoc numerical strategy to account for the contribution of the fibers in the simulation of the mechanical response of SFRC. In the model presented, the individual fibers immersed in the concrete bulk are accounted for in their actual location and orientation.

The idea is to define independent meshes and models for the two materials and couple them imposing displacement compatibility between them. Moreover, the chosen model for the fibers not only describes the behavior of these fibers, but also accounts for the interaction behaviour between the concrete bulk and the fibers.

2 COUPLING THE CONCRETE BULK AND THE FIBER CLOUD

The mesh corresponding to the concrete bulk is defined independently and non-conformal with the mesh of the fibers. All the fibers are discretized as 1D bars accounting for their actual geometry and distribution and overlapping the concrete domain. The concrete bulk can be discretized with 2D or 3D mesh, depending on the problem. Figure 1, shows these meshes.

Figure 1: Meshes corresponding to the concrete bulk, the fiber cloud and SFRC

This coupling, as described in [1], is done on the bases of the Immersed Boundary (IB) methods [2,3,4]. The IB methods are defined for solving problems with solids immersed on fluids. In this case, the fibers are playing the role of the solids immersed on the concrete (which takes the role of the fluid). Thus, apart from ensuring equilibrium in the concrete bulk and the fiber cloud, displacement compatibility is imposed between the two materials. Moreover, in the concrete equilibrium, the force of the fibers is included (by means of the Lagrange multipliers), and for the fibers, the equilibrium takes into account the reactions of the forces of the fibers to the concrete. Other authors [15] have proposed similar approaches using different numerical strategies.

-

BEFIB2012: Climent Molins and Alba Pros and Pedro Dez.

3

3 INDEPENDENT MODELS

For the concrete bulk and the fiber cloud, the material models are defined independently. In this section, first the possible models for the concrete and, then, the proposed mesomodel for the fibers are described, which describes both the steel fibers behavior and the concrete-fiber interaction.

3.1 Plain concrete

Concrete is a brittle material in tension, which can be modeled considering both continuous and discontinuous models. In [5] two different models are proposed for modeling plain concrete. On one hand, the nonlocal Mazars Damage model is chosen and, on the other hand, a discontinuous model defining the fracture pattern a priori with joint elements while the rest of the specimen is assumed to be elastic. These models can be used for modeling the concrete bulk for the proposed numerical tool for SFRC.

3.2 Fiber cloud and concrete-fiber interaction

The model considered for steel fibers accounts for the whole process of slipping and debonding of the fiber into plain concrete and, precisely, allows capturing the whole behavior between the fibers and the concrete bulk. Thus, an elasto-plastic angle dependent model with softening is adopted for the steel fibers. The interaction is modeled with the monolithic model imposing displacement compatibility described in the previous section.

An alternative approach would be considering steel fibers being modeled with an elasto-plastic model and the interaction between concrete and fibers defined describing the whole process (slipping, folding, debonding,etc.). Although the steel fiber model would be easy, the interaction is much more complex to perform.

The mesomodel for the steel fibers is expected to account for the whole interaction process between concrete and fibers and to characterize the behavior of the steel fibers. This aims at describing the effect of different phenomena, resulting in a global behaviour at the meso-scale. The mesomodel is assumed to include in a single constitutive relation the effects of the nonlinear behaviour of the steel, the slipping, folding, debonding and also the sliding of the fiber with respect to the concrete. Thus, the constitutive equations of steel fibers are deduced from experimental results and analytical descriptions of pullout tests.

Pullout tests consist of a plain concrete specimen with only one steel fiber immersed on it, which is pulled out. Fortunately, there is a recent analytical phenomenological description of pullout tests is available based on experimental results ([6,7]). These analytical expressions depend on the angle between the fiber and the load direction and on the shape of the fiber, which can be straight or hooked. The whole expressions are described in [1].

In general, the angle is computed between the fiber and the normal direction of the fracture pattern. However, for the pullout tests, the load direction is perpendicular to the failure pattern, therefore, the normal direction coincides with the load direction.

In the common situations the volumetric proportion of steel fibers into plain concrete is lower than 1%. In this case, the behaviour of the fibers inside concrete is the same as if it was isolated, and it is not necessary taking into the account the fiber-fiber interaction. However, if the volumetric proportion of fibers is larger than 1%, this assumption may be unrealistic. Accounting for the fiber-fiber interaction is out of the scope of this tool.

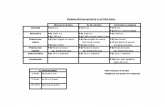

Therefore, for each fiber immersed in the concrete bulk, a different constitutive equation is considered depending on its shape (straight or hooked) and on the angle between the considered fiber and the normal direction of the failure pattern. In figure 2, different constitutive stress-strain equations are presented for different angles and considering both straight and hooked fibers. These equations are obtained through analytical expressions of the pullout tests and defined on the fiber axis, for 60 mm long fibers discretized in five bar elements 12 mm long. The reference length to compute the strains of Figure 2 is the one of the fiber elements: 12 mm.

-

BEFIB2012: Climent Molins and Alba Pros and Pedro Dez.

4

Figure 2: Stress-strain constitutive equations for different angles for straight (left) and hooked (right) fibers

4 EXAMPLES

In order to validate the proposed numerical tool, two experimental tests are reproduced numerically in this section. Moreover, the obtained results are compared to the experimental ones.

Two different fiber contents are considered: 20 kg/m3 and 40 kg/m

3, which correspond to 0.25%

and 0.5% volumetric substitution amount of fibers, respectively. Steel fibers used in the experiments are 60 mm long, with a diameter of 0.75 mm and hooked ends. The yielding strength of the steel is fy=2000 MPa. The concrete used in all experiments is self-compacting and with the same mix proportion.

Prior to simulate the tests with SFRC, they are simulated considering only plain concrete modeled through the nonlocal Mazars damage model. Then, the failure pattern of the test is determinated for (a) computing the normal direction of the failure pattern and, therefore, the angle of each fiber and the normal direction and (b) simulating the same test, but with the discontinuous model for the concrete bulk.

In all the simulations, each fiber is discretized considering 5 straight bar elements of 12 mm length, because all the fibers are 60 mm long. All the data and parameter information of these simulations are presented in [8].

4.1 Direct tension test

The direct tension test, illustrated in figure 3, consists of a cylindrical specimen (made of plain concrete or SFRC) with a circumferential notch of 5mm width and 15mm depth to localize the crack, axially loaded according to [9].

In figures 4 and 5 the obtained results considering different quantities of fibers are presented and compared to the corresponding experimental results. Moreover, the displayed numerical results are obtained modeling plain concrete with both the nonlocal Mazars Damage model and the discontinuous model using joint elements. In all the cases, fibers are randomly distributed.

Numerical simulations of the uniaxial tension test of the 0.25% fiber content are presented in Figure 4, whilst in Figure 5 are presented those with 0.50% of fiber content. For the particular case of 0.25% of volumetric substitution, a very good agreement between the experimental and the numerical results is achieved. It is worth to stress that the simulations produce, as expected, a sudden drop of the

-

BEFIB2012: Climent Molins and Alba Pros and Pedro Dez.

5

resisted tension after cracking and a limited recover of the stresses due to the contribution of fibers. They also present a flat section in the load - CMOD diagram, as detected in the experiments between 1 and 3 mm of CMOD. The residual peak tension strength is slightly higher in the simulations.

Numerical results with 0.5% of volumetric substitution shown in Figure 5 are significantly higher than those obtained experimentally, particularly when using the discrete joints model. To the authors, the most concerning results is the one produced by the joints model. However, the residual strength results obtained by the continuum damage model is approximately two times the strength obtained in the case of 0.25% of volumetric substitution, which is absolutely consistent when dealing with low fiber contents.

Figure 3: Direct tension test scheme

Figure 4: Results of the direct tension test with 0.25%

150 mm

150 mm

-

BEFIB2012: Climent Molins and Alba Pros and Pedro Dez.

6

Figure 5: Results of the direct tension test with 0.5%

4.2 Three point bending test

For studying the flexural behaviour of the SFRC, the three point bending test is reproduced with the numerical tool presented in this paper. The three point bending test consists of a beam placed horizontally and fixed in two points which is loaded in the middle of the top of the beam, as reproduced in figure 6, according to [10].

The simulation of the three point bending is done considering the nonlocal Mazars damage model and with a volumetric substitution of fibres of 0.25%. Three different cases are analyzed: 1) all the fibers distributed and oriented randomly, 2) fibers randomly distributed and all the angles equal to 0 and 3) fibers randomly distributed and all the angles equal to 30.

Figure 7 shows the load CMOD diagrams obtained experimentally and numerically. Some aspects to discuss is that, after cracking, the numerical model produce lower minimum loads than the experiments. In addition, for all ranges of CMOD, it can be observed that the simulated loads are lower than those obtained experimentally. The latter also occurs in the case of assuming that all fibers are oriented parallel to the stresses, (0 orientation). Of course, when the orientation of the fibers is more parallel to the stresses, as expected, the model produce higher loads.

-

BEFIB2012: Climent Molins and Alba Pros and Pedro Dez.

7

Figure 6: Three Point Bending test scheme

Figure 7: Results of the Three point bending test

5 LIMITS OF THE PROPOSED TOOL

Once the two 3D examples are reproduced numerically using the proposed numerical tool, some computational limits appeared. For a large number of fibers, the matrix of the system to be solved at each iteration of the incremental-iterative scheme is very large. Thus, the computational cost and time are high.

Each fiber is discretized into five elements. Increasing the number of fibers means increasing almost proportionally the computational cost.

In the examples presented in this paper, in order to reduce the computational cost, only the fibers crossing the failure pattern are finally included into the system. Although the computational cost is lower, it is not lower enough for large quantities of fibers.

Therefore, an alternative must be considered for being able to simulate larger and more realistic

-

BEFIB2012: Climent Molins and Alba Pros and Pedro Dez.

8

structures with SFRC considering the presented numerical approach. An alternative that has been devised is to consider the idea presented by in [11] in which the system is solved following a block Gauss-Seidel strategy.

9 CONCLUSIONS

In this work, a numerical tool for simulating SFRC which allows accounting for the actual geometry of the fibers into the concrete specimen is presented.

Both the concrete bulk and the fiber cloud are discretized non-conformal. The two materials are coupled imposing displacement compatibility between them. The concrete bulk can be modeled considering any nonlinear material. On the other hand, the mesomodel considered to be the constitutive model of the fiber cloud not only describes the steel fibers behaviour, but also accounts for the interaction behaviour between the fiber cloud and the concrete bulk.

Two realistic examples of experimental tests performed on SFRC specimens are simulated using the proposed tool in order to validate it: uni-axial tension tests and three point bending tests.

The influence of the fibers is clearly noticed in the results in terms of residual strength, which increases comparing to the results obtained simulating the same tests with only plain concrete. For a higher number of fibers into the plain concrete, the residual strength of the SFRC is higher.

This tool allows to accurately reproduce the fibers distribution and orientation in order to obtain realistic results.

All the numerical results presented in this paper are achieved by generating the fiber cloud randomly. However, preferred orientations are observed in the SFRC specimens used in the experimental campaigns (for the direct tension test [12] and the three point bending test [13]). Therefore, the numerical results obtained taking into account these preferred orientations of the fibers should fit better with the experimental results.

For a large number of fibers, the computational cost is too high. Therefore, we should seek an alternative to solve efficiently the system of the problem.

Up to now, the presented examples have a fracture pattern well defined and with only one crack. The next step is to reproduce a test with SFRC with a fracture pattern not so easy to describe, for example the Barcelona Test [14]. The used technique is the same, but it is necessary to take into account the position of each fiber and the corresponding normal direction to the failure pattern in this current position.

REFERENCES

[1] A. Pros, P. Dez and C. Molins, Modeling Steel Fiber Reinfoced Concrete: numerical immersed boundary approach and a phenomenological mesomodel for concrete-fiber interaction, International Journal of Numerical Methods in Engineering. Accepted for publication (2011).

[2] D. Boffi and L. Gastaldi, A finite approach of the immersed boundary method, Computers and Structures, 81, 491-501 (2003).

[3] D. Boffi, L. Gastaldi and L. Heltai, On the CFL condition for the finite element immersed boundary method, Computers and Structures, 85, 775-783 (2007).

[4] R. Mittal and G. Iaccarino, Immersed Boundary Method, Annu Rev Mech, 37, 239-261 (2003). [5] A. Pros, P. Dez and C. Molins, Numerical modeling of double punch test for plain concrete,

International Journal of Solids and Structures, 48 (7-8), 1229-1238 (2011). [6] F. Laranjeira, A. Aguado and C. Molins, Predicting the pullout response of inclined straight steel

fibers, Materials and structures, 43, 875-895 (2010). [7] F. Laranjeira, C. Molins and A. Aguado, Predicting the pullout response of inclined hooked steel

fibers, Cement and Concrete research, 40, 1471-1487 (2010). [8] A. Pros, Numerical approach for modeling Steel Fiber Reinforced Concrete, PhD Thesis,

Universitat Politcnica de Catalunya, 2012.

-

BEFIB2012: Climent Molins and Alba Pros and Pedro Dez.

9

[9] RILEM TC 162-TDF, Recommendations of RILEM TC 162-TDF: Test and design methods for steel fibre reinforced concrete. Uniaxial tension test for steel fiber reinforced concrete, Materials and structures, 34 (235), 3-6, 2001.

[10] RILEM TC 162-TDF, Test and design methods for steel fibre reinforced concrete: bending test. Recommendations, Materials and structures, 33, 3-5, 2000.

[11] A. Pros, P. Dez and C. Molins, Numerical modeling of a test assessing the tensile strength of steel fiber reinforced concrete, In the 8

th world congress on Computational Methods in Applied

Sciences and engineering (ECCOMAS 2008), Venice, Italy, 2008. [12] F. Laranjeira, Design-oriented constitutive model for steel ber reinforced concrete, PhD Thesis,

Universitat Politcnica de Catalunya, 2010. [13] C. Molins, J. A. Martnez and N. Arniz, Distribucin de fibras de acero en probetas prismticas

de hormign, In Congreso Internacional de estructuras, IV, Congreso ACHE, Valencia, Spain, 304-305, 2008.

[14] C. Molins, A. Aguado and S. Saludes, Double Punch Test to control the energy dissipation in tension of FRC (Barcelona Test), Materials and Structures, 42, 415-425, 2009.

[15] V. Cunha, J. Barros, J.S. Cruz, " A finite element model with discrete embedded elements for fibre reinforced composites", Computers and Structures, 9495, 22-33, 2012.