SOY REBOUNDS

-

Upload

alexander-h -

Category

Documents

-

view

213 -

download

0

Transcript of SOY REBOUNDS

BUSINESS

SOY REBOUNDS Soybeans are once again garnering attention as

a RENEWABLE raw material for polymers ALEXANDER H. TULLO, C&EN NORTHEAST NEWS BUREAU

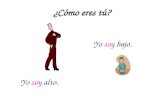

SOYBEANS FASCINATED Henry Ford. In this crop, which is rich in oil and protein, he saw great potential to marry agriculture and industry. He grew soybeans, ate soybean-based food, and even donned a suit made of soy-protein fibers.

And under Henry Ford's direction, Ford Motor Co. developed a plastic derived from soybeans. He publicly took an ax to automobile parts made with this plastic to demonstrate its strength. In 1941, the company even unveiled a concept car with body panels made entirely from the plastic.

The push for soy-based materials fell by the wayside during World War II. But no doubt Henry Ford would be pleased to learn that polymers made from soybeans are once again catching on. The polymers are chemically far more sophisticated than they were in the 1940s. Experts say his "soybean plastic" was most likely a phenolic resin incorporating soybean filler.

Today, chemists and materials engineers are using soybean oil to synthesize poly-ols—molecules with multiple hydroxyl groups—and react them with isocyanates to make polyurethanes. They're also incorporating soybean oil into the polymer backbones of unsaturated polyester resins to make composite parts.

Biobased materials such as polylactic

acid and 1,3-propanediol, used to make polytrimethylene terephthalate, often have to slug it out it out in the polymer industry as a new-to-the-world material challenging entrenched polymers. Soy-based polyols, on the other hand, are intended to replace a portion of the familiar polyols made from petrochemically derived propylene oxide in conventional polyurethane formulations.

The potential for replacement is huge. The annual market for conventional polyols is about 3 billion lb in the U.S. and 9 billion lb globally, according to the United Soybean Board (USB).

Chemical companies such as Dow Chemical, start-up firms, and the agricultural processing giant Cargill are all bringing soy polyols to the market.

Polyols aren't commodity chemicals; they are tailor-made and reacted with isocyanates for specific applications. That's why the makers of the new soy polyols see many opportunities. "There are hundreds of petrochemical-based polyols out there on the market, and each one is targeted to be especially effective in a particular use," says Tom Muccio, chief executive officer of soy polyol start-up BioBased Technologies in Rogers, Ark. "We think that at some point in time the same will be true of biopolyols."

BOLD MOVE Henry Ford hacks away at his car to demonstrate the strength of its trunk made of soy plastic.

Eric Geiger, director of R&D for Volga, S.D.-based Urethane Soy Systems, says the soybean-oil triglyceride origin of the biopolyols gives them an advantage over conventional polyols. He explains that

^ ^ ^ the biopolyols are not hy-drophilic like polyester and

polyether polyols, and thus they are less prone to hydrolysis. "You don't want your car seat to fall apart because water gets into the part and attacks the polymer," he says.

The companies that make the soy polyol say the materials provide a benefit to the environment. For instance, Geiger says that every pound of his company's polyol sequesters 2.7 lb of carbon dioxide from the atmosphere.

Backers say the environmental benefits don't come with a high manufacturing expense. Phil Sarnacke, a consultant with Omni Tech International, a contractor for USB, says most soy polyols are priced equal to or less than their petrochemical counterparts. This may seem counterintuitive. Biodiesel, which is also a soybean oil derivative, needs government subsidies to compete with conventional diesel fuel. But diesel fuel, Sarnacke explains, sells for only a fraction of the price that polyols do. "Soybean oil can't make it in biodiesel without subsidies, but these other products can because they are more valuable," he says.

There have been obstacles to making soy polyols practical. One is the odor, akin to burned popcorn. Debbie Mielewski, technical leader for Ford's materials research and advanced engineering department, says applying heat and oxygen to soybean oil to make the polyols generates odor-causing by-products. Fixes include encapsulating the materials to block the odor or stripping out the offending components through a thin-film distillation process. Ford says it also has developed a process of producing the polyols using ultraviolet light instead of heat. The end result of efforts like these, according to producers, is that soy polyols no longer have odor problems.

If Ford still worried about odor, it wouldn't be incorporating soy polyols in seats of the 2008 Mustang starting this month. Ford has been working on polyurethane foams incorporating soy polyols since 2001. Along the way, company researchers honed the properties of the soy-based materials to the point where they could meet the stringent physical properties that

WWW.CEN-0NLINE.ORG 36 AUGUST 20, 2007

consumers expect from automotive seating, Mielewski says. "Looking at different surfactants and different chemicals that will control cell structure, size, and distribution, we finally came up with something that passed all of our specifications," she says.

The company first used the foams in the Model U concept car in 2003. The following year, the company started working with USB, seat manufacturer Lear Corp., and Bayer MaterialSciences to develop materials suitable for commercial vehicle seats.

ONLY ABOUT 10% of the polyol in the Mustang seats will be derived from soy, but that percentage is likely to go up in time. Ford says it has developed foams in the laboratory that can bring soy polyol levels up to about 40%. The company calculates that the higher levels of incorporation, rolled out across its product line, could save $26 million annually.

Urethane Soy Systems is supplying the soy polyols used in the foam for the Lear seats. Since its founding in 1998, the company has developed two processes for making the polyols. One is an autoxidation process, which puts hydroxyl groups onto the triglyceride in the vicinity of unsaturated bonds. Another is a transesterification process whereby the chains on the triglyceride are reorganized and reacted with alcohols. The company has a polyol plant in Volga that started up in 2003. The plant has a capacity of 75 million lb per year.

Another start-up, BioBased Technologies, was founded in 2003 and uses a chemistry that oxidizes the unsaturated bonds of the triglyceride. The firm has three families of products, with 96,70, and 60% incorporation of biobased content.

The company's first client was Universal Textile Technologies, which is using the soy polyols to make carpet backing and artificial turf. Johnson Controls has started to make automotive seats incorporating BioBased Technologies' polyols to replace 5% of the foam's content.

The small company has had some assistance from big players in conventional polyurethanes. For a year, it has worked with Bayer MaterialScience and BASF in joint development agreements.

The world's largest maker of petrochemical polyols, Dow, also has an effort in soy polyols. Its chemistry starts with the breakdown of triglycerides into methyl esters via transesterification, the same process used to make biodiesel, says Erin O'Driscoll, business development manager for Dow's

polyurethanes business. The company then hydroformylates the methyl esters to add aldehyde groups to the unsaturated bonds. Ahydrogenation step then converts the aldehyde groups into alcohols. These molecules function like monomers and are combined with polyether polyols to build the new polyol. Although the molecules aren't wholly soy-based, O'Driscoll says,

WWW.CEN-0NLINE.ORG 'IH AUGUST 20, 2007

a majority of their content is renewable. Dow says its unique route to the polyols

provides flexibility. "With our approach, we have a lot of control over the architecture of the polyol," O'Driscoll says. "This is a chemical industry approach. We are interested in monomeric species. We understand what their structure is. And we can choose how we will use them, just

Berger SFC

With Thar Instruments' acquisition of Berger SFC* With our combined resources and technology of METTLER TOLEDO, the two top companies in expertise, we can drive toward new and Supercritical Fluid Chromatography (SFC) have innovative pharmaceutical solutions to joined forces to further the initiatives in drug separation solutions that:

discovery. And the benefits to the pharmaceutical , A d v a n c ? SFC technology • industry are more than the sum of the parts. We now serve the top 10 pharmaceutical companies, ' Eliminate bottlenecks in drug discovery

and provide a single source supplier for a complete . Provide more options and more applications range of SFC solutions in the analysis and purifica- P , . . .

* f . . , . . • ,. ,. • Expand global customer support tion of chemical compounds during drug discovery. And together, we will advance SFC technology to provide you with more options, more applications, \ 's'( »»>nl ls i Inicnumonal ( onkrcikv on Si (

and more customer support. u wu .pvaidieniisirvgroup.orii

412.967.5665

sfcCuMhiirtech.com

www.thartech.com

The Power of SFC2

Join Us at the Analytical Pavilion Applications in D r u g Discovery

Tuesday, August 21, 2007 ACS Fall National Meeting & Exposition

Boston Convention Center Exhibition Floor Analytical Sponsored by Q & £ N

Schedule of Events Complimentary Breakfast 9:00 a.m.-10:00 a.m.

Morning Keynote Address: 10:00 a.m. xThe Modern Pharmer: Analytical Technologies in Drug Discovery"

Presenter Dr. Adrienne A. Tymiak, Executive Director, Bioanalytical and Discovery Analytical Sciences, Bristol-Myers Squibb

Case Study Presentations Bruker 10:40 a.m. Shimadzu Scientific 11:20 a.m. Applied Biosystems 12:00 p.m.

0 S H I M A D Z U

Appl ied Biosystems

I R I I K E R

Afternoon Keynote Address: 1:30 p.m. "Analytical Challenges in Drug Discovery"

Presenter Dr. Guy T. Carter, Assistant Vice President, Chemical Technologies, Chemical & Screening Sciences, Wyeth Research

Case Study Presentations Bruker 2:10 p.m. Waters 2:50 p.m. Waters 3:30 p.m. Dionex 4:10 p.m.

D I O N E X Waters THE SCIENCE OF WHAT'S POSSIBLE."

The Analytical Pavilion

Sponsored by C&EN with support from the ACS Division of Analytical Chemistry, the Analytical Pavilion is an opportunity to discover Whafs New, Whafs Better in Analytical Applications. ACS & C&EN recognize the

importance of analytical chemists to the chemical enterprise.

wv* ry.o: ion

BUSINESS

as we would with any other monomer." Later this year, the company intends to

start a market development plant at the Houston facility operated by its custom synthesis business, Dow Haltermann, where Dow also makes biodiesel on a contract basis for clients.

Cargill says its offering was the "first commercially successful biobased polyol" used in flexible foam applications. The company won't reveal many details about its chemistry, developed with Pittsburg State University's Kansas Polymer Research Center and which earlier this year won a Presidential Green Chemistry Challenge Award (C&EN, July 9, page 35).

Cargill boasts it was shipping commercial volumes of product by late 2005, only 26 months after initiating the project. Its major customers include Hickory Springs Manufacturing, which makes foams for furniture and bedding, and the Woodbridge Group, which makes polyurethane foams for the automotive industry. Cargill manufactures the products through a toll arrangement with a third party but will construct its own plant as demand requires.

PONY'S NEW SADDLE The 2008 Ford Mustang will use a seat incorporating materials made from a soy polyol.

Polyols aren't the only soy-based materials that are making inroads into conventional polymer markets. Ashland has developed partially soy-based unsaturated polyester resins, trademarked as Envirez.

In Ashland's process, soybean oil and ethanol are reacted directly with the conventional unsaturated polyester components maleic anhydride and glycols. The ethanol and soybean oil replace some of the maleic anhydride and glycols in the polymer, which has about 25% biobased content and is used as a matrix resin for fiberglass composite parts.

John Deere and Ashland started to develop the polymers together in 1999. And with some funding from USB, the two companies rolled out their first commercial

application, press-molded side § panels for combines, in 2002.

Roman Loza, a research fellow at Ashland, says his company's pri

mary focus will be on press-molding processes, which are used to make

products such as doors and above-the-water-line parts on boats. He adds that

Envirez could eventually be applicable to other unsaturated polyester fabrication processes such as open molding.

Ashland claims that a 38,000-lb batch of Envirez sequesters 34,000 lb of C02 from the atmosphere. Stephanie Carter, industry manager for infrastructure at Ashland, says this green appeal has been a big driver for Envirez. "There are companies that have come up to us and said, We want some biobased products in our portfolio,'" she says.

But Carter stresses that costs and quality have to be comparable. "One of the things we have really worked hard to achieve is that the resins we introduce commercially are all drop-in replacements for their petroleum-based cousins," she says. "We do not expect customers to make process changes to handle sustainable resins." •

Cuvettes meetingthe H i g h e s t Qua l i t y standards

G u a r a n t e e d C o m p a t i b l e with your make and model

E f f o r t l e s s ordering, and reliable customer service

\j y i I j j j t i

Complete line of cuvettes Spectrophotometer cells Fluorometer cells Dye laser cells Flow cells Sub-micro cells Tablet dissolution cells ...and much more

Precision Cells, Inc. j *W +l-631-249-7474tel +1-631-249-857 5fax

hmf [email protected] www.nsgpci.com Cuvettes of highest quality. Code for 10% off: CE071CP

X = H, Br CA90004, 90005

OH

N NH 2

R = H, CH3

CA30001, 30002

"CI

V H C I CA30006

N CHO H

CA50008

OH

H O ^ N ^ N

C02Me

SMe

tVNH2

R = H, CH3

CA90030, 90031

CA90001

k n T - N H 2

I I ^N^NHCbz

H

k^NBoc

CA40001

N 0 2

Br

CA41010

Boc

Br

N 0 2

S 0 2 C H 3

NC.

cr r CA50011

CI

NH2 .HCI

CA50007

V

Prefer an experienced while nimble chemistry partner ...

Have a tight budget but a demanding deadline ...

Desire flexibility due to constantly changing priority ...

Give us a call or drop an email

c CHEMALONG The TzigktfcapUf The night chemistry

Ph: 630.257.9683 Fax: 630.257.9684 Email: [email protected]

WWW.CEN-0NLINE.ORG 2 Q AUGUST 20, 2007