Reportes

20

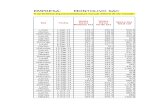

Availabilty & U tilization January February March April M ay June July August Septem ber October Novem ber Decem ber 40 50 60 70 80 90 100 % Availability U tilization Target R eliability M TBF January February M arch April M ay June July A ugust Septem ber O ctober Novem ber D ecem ber 0 20 40 60 80 100 MTBF (H ours) MTBF Target Mean Time to R epairMTTR January February M arch A pril M ay June July August Septem ber O ctober N ovem ber Decem ber 1 2 3 4 5 6 7 MTTR(hours) M TTR Target MTTR w/o Delays Maintenance R atio MR January February M arch April M ay June July A ugust Septem ber O ctober N ovem ber D ecem ber 0 0.1 0.2 0.3 0.4 0.5 0.6 Lab or/O p.hours MR Target Availabilty & U tilization January F ebruary M arch April M ay June July August Septem ber O ctober N ov em ber D ecem ber 40 50 60 70 80 90 100 % A vailability U tilization Target Reliability M TBF January February March April May June July August Septem ber October N ovem ber D ecem ber 0 20 40 60 80 100 M TB F (Hours) MTBF Target Mean Time to R epairMTTR January February March April M ay June July August Septem ber O ctober N ovem ber Decem ber 1 2 3 4 5 6 7 M TTR (hours) M TTR Target MTTRw/o Delays Maintenance R atio MR January February M arch April M ay June July August Septem ber O ctober Novem ber D ecem ber 0 0.1 0.2 0.3 0.4 0.5 0.6 Labor/O p .hours MR Target 5 25 45 65 85 105 125 142 162 182 60 70 80 90 100 D isponibilidad % Reportes para la Reportes para la Gestión del Gestión del Mantenimiento Mantenimiento

-

Upload

ronald-chang -

Category

Documents

-

view

212 -

download

0

description

Reportes de gestión de equipo pesado.

Transcript of Reportes

RESUMEN REPORTESReportes para la Gestión del Mantenimiento

Managing the Tools for Mining Buenos Aires

Produccion

Analysis

Arbol de decisión del RCM :

Funciones Evidentes

P

¿Es posible Programar la reparación ,restaurar la función y reducir la probabiilidad de Falla?

¿Puede usted reemplazar facilmente el item, y con esto reducir la taza de fallas?

si

causa simple de detectar

causa simple de detectar

causa afecta la seguridad de

trabajadores o medioambiente o

causa afecta la seguridad de

trabajadores o medioambiente o

Proveniente de esta causa afectan

a la producción directamente

si loscostos asociados a este son

menores que las de pérdidas de producción

Inspección,Monitoreo

PCR

Availabilty & Utilization

January

February

March

April

May

June

July

August

September

October

November

December

1

2

3

4

5

6

7

January

February

March

April

May

June

July

August

September

October

November

December

1

2

3

4

5

6

7

0

100

200

300

400

500

0

0.5

1

1.5

2

2.5

3

3.5

Budget

Actual

Budget

Actual

GENERAL PERFORMANCE METRICS

January

February

March

April

May

June

July

August

September

October

November

December

1

2

3

4

5

6

7

Corrective Actions

December 199x (last month)

December 199x (last month)

July

August

September

October

November

December

0

10

20

30

40

Months

-

The Benchmarks or Targets for Quantity, ETTR will be established. It is noticeable the increase of Backlogs and estimated time to repair them (ETTR).

This is very dangerous; we have to improve our reaction (clean BL List). The Nbr. of BL executed is low and constant. The quantity of Backlogs waiting for

being process is affected by the location of the warehouse. The BL waiting for parts are affecting directly on the age of them, BL (>30)

Corrective Actions

-

Considering the amount of BL "ready to go" (Green) we will start scheduling more BL within the planned activities and instructing the supervisors to

increase the use of the window of opportunities of the unscheduled repairs.

- We are working in the relocation of the warehouse.

- We will increase the scheduling of BL and the shop will be instructed to executed 100 % of the planned jobs.

Backlogs per System

240 Ton Truck Fleet

our BL system.

ples. We will include the actual data in the

next report.

operators. We are reviewing our procedures

to ensure the proper handling of operator

feedback.

4.0%

5.0%

7.0%

27.0%

9.0%

25.0%

11.0%

8.0%

4.0%

Engine

XMSN/TC

Dif/Finals

Electrical

Frame

Hydraulic

Tires

PMs

Others

10.0%

8.0%

7.0%

7.0%

12.0%

28.0%

10.0%

17.0%

1.0%

Engine

XMSN/TC

Dif/Finals

Electrical

Frame

Hydraulic

Tires

PMs

Others

January

February

March

April

May

June

July

August

September

October

November

December

20

40

60

80

100

120

140

Training Hours per System

90.00

79.12

Managing the Tools for Mining Buenos Aires

Produccion

Analysis

Arbol de decisión del RCM :

Funciones Evidentes

P

¿Es posible Programar la reparación ,restaurar la función y reducir la probabiilidad de Falla?

¿Puede usted reemplazar facilmente el item, y con esto reducir la taza de fallas?

si

causa simple de detectar

causa simple de detectar

causa afecta la seguridad de

trabajadores o medioambiente o

causa afecta la seguridad de

trabajadores o medioambiente o

Proveniente de esta causa afectan

a la producción directamente

si loscostos asociados a este son

menores que las de pérdidas de producción

Inspección,Monitoreo

PCR

Availabilty & Utilization

January

February

March

April

May

June

July

August

September

October

November

December

1

2

3

4

5

6

7

January

February

March

April

May

June

July

August

September

October

November

December

1

2

3

4

5

6

7

0

100

200

300

400

500

0

0.5

1

1.5

2

2.5

3

3.5

Budget

Actual

Budget

Actual

GENERAL PERFORMANCE METRICS

January

February

March

April

May

June

July

August

September

October

November

December

1

2

3

4

5

6

7

Corrective Actions

December 199x (last month)

December 199x (last month)

July

August

September

October

November

December

0

10

20

30

40

Months

-

The Benchmarks or Targets for Quantity, ETTR will be established. It is noticeable the increase of Backlogs and estimated time to repair them (ETTR).

This is very dangerous; we have to improve our reaction (clean BL List). The Nbr. of BL executed is low and constant. The quantity of Backlogs waiting for

being process is affected by the location of the warehouse. The BL waiting for parts are affecting directly on the age of them, BL (>30)

Corrective Actions

-

Considering the amount of BL "ready to go" (Green) we will start scheduling more BL within the planned activities and instructing the supervisors to

increase the use of the window of opportunities of the unscheduled repairs.

- We are working in the relocation of the warehouse.

- We will increase the scheduling of BL and the shop will be instructed to executed 100 % of the planned jobs.

Backlogs per System

240 Ton Truck Fleet

our BL system.

ples. We will include the actual data in the

next report.

operators. We are reviewing our procedures

to ensure the proper handling of operator

feedback.

4.0%

5.0%

7.0%

27.0%

9.0%

25.0%

11.0%

8.0%

4.0%

Engine

XMSN/TC

Dif/Finals

Electrical

Frame

Hydraulic

Tires

PMs

Others

10.0%

8.0%

7.0%

7.0%

12.0%

28.0%

10.0%

17.0%

1.0%

Engine

XMSN/TC

Dif/Finals

Electrical

Frame

Hydraulic

Tires

PMs

Others

January

February

March

April

May

June

July

August

September

October

November

December

20

40

60

80

100

120

140

Training Hours per System

90.00

79.12